Your vehicle’s braking system is a critical safety component. While drivers react to obvious signs like squealing or grinding brakes or increased stopping distance, many are unaware of how thorough a professional brake inspection is.

A professional brake inspection examines the entire braking system, not just the pads, to ensure optimal function and driver safety. Understanding this process helps drivers proactively maintain vehicle safety and avoid costly repairs from neglected brakes.

By recognizing the nuances of this essential service, drivers can make informed decisions that safeguard both their well-being and their financial security in the long run.

Examining Brake Pads and Shoes

Typically, brake pads and shoes are the first components a technician examines during an inspection due to their susceptibility to wear. The technician will assess their remaining lifespan by measuring their thickness. If these parts are excessively worn, it can result in metal-on-metal contact, causing damage to the rotors or drums and subsequently increasing repair expenses.

By identifying early wear, the inspection allows drivers to replace pads or shoes before they create further problems. Even if there are no unusual noises or vibrations, regular evaluations of these components ensure safe stopping performance.

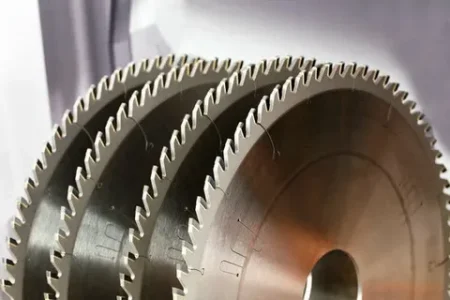

Assessing Rotors and Drums

During a brake inspection, mechanics examine rotors and drums for wear, scoring, or warping. Damage can cause vibrations; if minor, resurfacing is an option. Severe thinning or damage requires replacement for safety and efficiency.

Ignoring these signs can lead to longer stopping distances, brake fade, and even complete brake failure, putting drivers and passengers at significant risk. Regular inspections can catch these issues early, allowing for timely replacement and preventing more costly repairs or dangerous situations down the line.

Inspecting Brake Lines and Hoses

A professional brake inspection includes a thorough check of brake lines and hoses. These components are vital for carrying hydraulic fluid from the master cylinder to the brakes at each wheel. Inspectors look for leaks, cracks, and corrosion, as even minor leaks can severely compromise braking power.

They also check for swelling in hoses, which can impede fluid flow. Maintaining the integrity of these parts is crucial for consistent hydraulic pressure and reliable stopping power.

Checking Brake Fluid Condition

Brake fluid is a critical yet often overlooked part of the system. Since it absorbs moisture over time, the fluid can become contaminated, reducing its effectiveness. During the inspection, the mechanic checks the fluid level and evaluates its condition. Dark or dirty fluid often signals that it is time for a flush. Maintaining clean fluid prevents corrosion within the brake system and ensures consistent performance under pressure.

Evaluating the Parking Brake

Technicians also meticulously inspect the parking or emergency brake, a crucial yet often underutilized safety feature. It maintains vehicle stability on inclines and acts as a vital backup during emergencies. The inspection tests its engagement and adjusts cable tension if needed.

The technician will inspect all connected components, including the parking brake cable, levers, and mechanical linkages, for wear, corrosion, or damage. The parking brake is vital in hilly areas or when towing heavy loads, adding a crucial safety layer to prevent unintended vehicle movement.

Reviewing the Master Cylinder

The master cylinder is the braking system’s critical heart, converting brake pedal force into hydraulic pressure evenly distributed to all wheels for safe, controlled stops. Mechanics thoroughly inspect the master cylinder during a brake inspection, checking for fluid leaks, proper fluid distribution to each wheel, and overall function, including internal seals, pistons, and reservoirs.

Master cylinder issues present clear symptoms: a “spongy” brake pedal indicates hydraulic pressure loss or air in the lines, while uneven braking suggests inconsistent pressure distribution. Early detection and repair are vital for braking system safety and performance, preventing further deterioration and accident risk. Regular inspections can identify problems before they worsen.

Understanding the Value of a Comprehensive Inspection

A professional brake inspection is more than just a quick glance at the pads. It is a detailed evaluation that looks at the system as a whole. This thorough process helps identify wear, prevent failures, and give drivers peace of mind.

For instance, many local auto shops, such as Reliable Auto Repair, emphasize the importance of regular inspections not just for safety but also for extending the life of the braking system. By catching small issues early, drivers can avoid the larger expenses and risks associated with neglected brakes.

Prioritizing Safety Through Regular Maintenance

Scheduling regular brake inspections is a proactive step toward ensuring road safety. Even if the brakes seem fine, hidden issues can affect their performance without noticeable symptoms. By understanding what professionals look for during an inspection, drivers gain clarity about their vehicle’s condition and can make informed decisions about maintenance.

Regular checks not only keep the car running safely but also provide reassurance that the system is ready for any driving condition.